Product description Corner Castings

Corner Castings

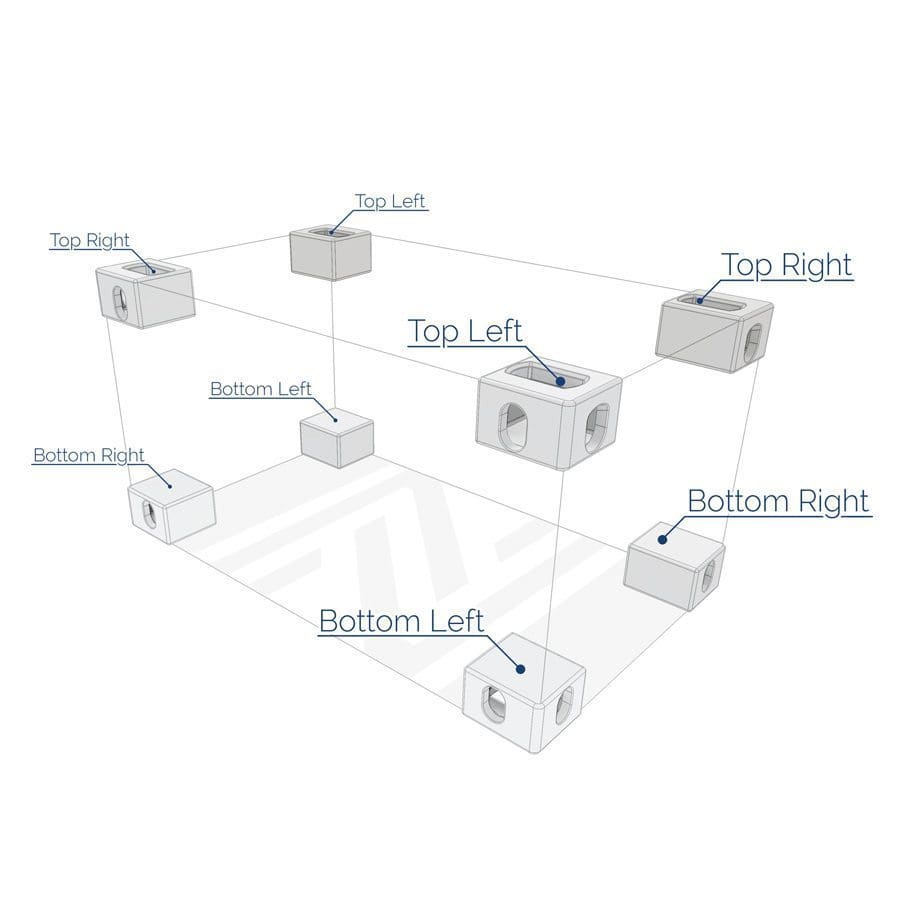

Corner Castings is a commonly used name for the corners of a shipping container. These cast steel corners are suitable for containers, a self-designed structure, or repair works. Our Corner Castings are produced according to international ISO standards (1161:2016). This product is available in 4 variants: Top Left, Top Right, Bottom Right and Bottom Left. Each corner block is made of heavy-cast steel and is treated with a protective primer coating. Due to the high-quality cast steel, this Corner Casting has a tested breaking strength of 50T. You can find the exact dimensions of the Corner Castings in the technical drawing.

Suitable for corners of shipping containers or similar constructions

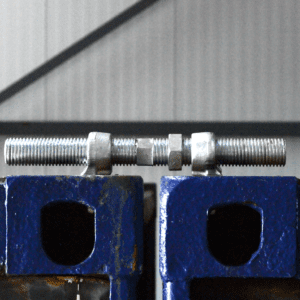

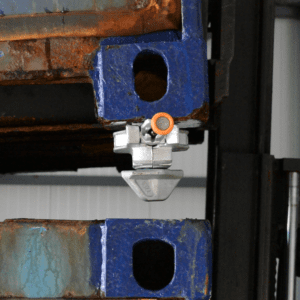

The Corner Castings are suitable for multiple purposes. The cast steel corner pieces are ideal for repairing used containers or building new containers. These Corner Castings may also be used in self-designed constructions. The standardised dimensions make it possible to place the structure on the deck of a ship, a pontoon or on top of another shipping container. Once situated, a container can be secured easily, utilising intermediate or dovetail twistlocks.

Produced according to international ISO 1161:2016 standard

The Corner Castings are manufactured according to the international ISO standard (1161:2016). Because of this standard, the product can be used for all standard 10, 20, 30, 40 and 45-foot (Ft.) shipping containers worldwide. The Corner Castings are also fully compatible with all variants of twistlocks in the Navacqs range. The most commonly used twistlocks are the Dovetail BF-11 twistlock for use under a shipping container and the intermediate IF-51 twistlock for locking between two stacked containers.

Set of 4 (bottom or top) or 8 pieces (complete container)

A standard shipping container consists of 8 corner castings in total. Seen from the front of the container (where the doors are located), the two corners at the bottom are the “Bottom Left” and “Bottom Right”. The same applies to the top from the end of the container. The “Top Left” and “Top Right” corner blocks are mounted on the corner points.

Each corner piece can be ordered separately. It is also possible to order the corner castings per set. A set consists of 4 corner castings, suitable for attaching to the bottom or top of a construction. The corner castings are also available for purchase as a set of 8 pieces for a complete shipping container or similar structure.

The “Set Top” consists of:

- 2x Corner Casting “Top Left”

- 2x Corner Casting “Top Right”

The “Set Bottom” consists of:

- 2x Corner Casting “Bottom Left”

- 2x Corner Casting “Bottom Right”

The “Set Complete” consists of:

- 2x Corner Casting “Top Left”

- 2x Corner Casting “Top Right”

- 2x Corner Casting “Bottom Left”

- 2x Corner Casting “Bottom Right”

Manufactured from cast steel and “primer coated”

Navacqs Corner Castings are made out of heavy cast steel (SCW480). Thanks to this material, Corner Castings have a tested breaking strength of 50T. Each corner casting is treated with a unique, paintable primer coating. This primer prevents the corner pieces from corrosion. The primer does not affect the quality of the weld, so there is no need to remove it before welding. However, smoke development can occur during welding. If desired, you can remove the primer.

In addition to the protective features, the primer also ensures a good adhesion for any other paint for finishing. The product is suitable for painting or spraying without further additional treatment.

Technical drawing available

The exact dimensions of the Corner Castings are available on the technical drawing in .pdf format. A drawing of both the Corner Casting Top Left and the Corner Casting Bottom Left is available. There is also a 3D drawing available as a .stp file. This file format allows embedding the Corner Castings into a technical 3D drawing to design your constructions. For questions and free advice, our sales team is ready to help. Please get in touch with us via +31 (0) 10-495 0000 or sales@navacqs.com to discuss the possibilities. You can also contact us if you are looking for a similar product that is not on our website.

The Corner Castings are similar to the following items from other manufacturers

1-12-15-BL, 1-12-15-BR, 1-12-15-TL, 1-12-15-TR, CO-BL, CO-BR, CO-TL, CO-TR, 1- 12-15-BL, MK-OB, MK-OBL, MK-OBR, MK-OT, MK-OTL, MK-OTR