|

Product

|

Deck socket DF-31

|

|

Breaking strength

|

500 Kn (≈50 T) |

|

Material

|

Cast steel |

|

Finish

|

Blasted and treated with primer (directly weldable) |

|

Weight

|

3,7 Kg

|

|

Quality steel

|

SCW480

|

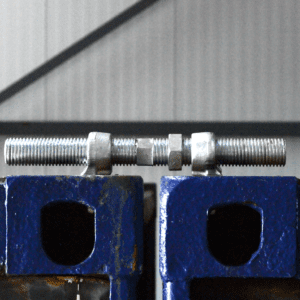

Deck Socket DF-31

Deck Socket DF-31

- Makes the BF-11 Twistlock and Lashing Eye LP-91-45 demountable

- Easy to weld onto ship deck or construction

- High breaking strength of 500 kN (T) / 420 kN (SH)

- Manufactured from steel with primer coating

- Technical drawing available (Download)

| Quantity from | 1+ | 4+ | 8+ | 16+ | 24+ | 32+ |

|---|---|---|---|---|---|---|

| Price per piece | €39.50 | €33.50 | €30.50 | €28.00 | €26.00 | €23.50 |

Bodemplaat DF-31

The Deck Socket DF-31 bottom plate makes it possible to use the Dovetail Twistlock BF-11 and the U-Frame Lashing Eye (D-Ring) LP-91-45. The deck of a ship (or another surface) thus remains free of protruding twistlocks or lashing eyes. Thanks to the well-thought-out design and use of materials, the DF-31 bottom plates have a tested breaking strength of no less than 500 kN or 50T. The frame is made of cast steel and finished with a protective primer. The exact dimensions of the Bottom plate DF-31 can be found on the technical drawing.

Makes the BF-11 Twistlock and Lashing Eye LP-91-45 demountable

The Deck Socket DF-31 has been specially developed for use in combination with the Dovetail Twistlock BF-11. With this twistlock, a sea container can be secured on deck. The DF-31 bottom plate ensures that the twistlock can be disassembled. The deck socket is designed in such a way that the BF-11 can easily be slid into the socket. This keeps the deck of a ship (or another surface) free from protruding twistlocks or lashing eyes.

The Deck Socket DF-31 also serves as the basis for the U-Frame Lashing eye (D-Ring) LP-91-45. This 36-tonne lashing eye is used to lash cargo. This can be useful in a situation where different types of loads are being transported. For example, a container can be transported on the same deck one day and a steel structure has to be lashed the next day. The base plate DF-31 is supplied with an inner angle of 45 degrees as standard. The Deck Socket DF-31 is optionally available with an angle of 55 degrees.

Both the LP-91-45 and the BF-11 can only be slid in one direction in the bottom plate.

The plates must be welded in the opposite direction. When the Dovetail Twistlock is placed in the opposite direction in the bottom plate and the container is in place, shifting is no longer possible.

Easy to weld to ship deck or construction

The versatile base plates from Navacqs can easily be welded to a steel surface. For example on the deck of a ship or a floating pontoon with offshore equipment. In addition to applications on the water, the Deck Socket DF-31 can also be welded on trailers to anchor self-designed structures. The welding instructions can be downloaded here.

Please note: the Deck Socket DF-31 is not suitable for road transport. For this application use a suitable twist lock with security.

High breaking strength of 500 kN (T) / 420 kN (SH)

Heavy forces can stand on the Dovetail Twistlocks and U-Frame Lashing Eyes. Especially when containers or structures are subject to severe weather influences such as strong wind in combination with a. have to cope with waves. The bottom plate DF-31 is the connecting factor between the twistlock and the ground. Thanks to the well-thought-out design and use of materials, the DF-31 bottom plates have a tested breaking strength of no less than 500 kN or 50T.

Manufactured from steel with primer coating

The Base plate DF-31 from Navacqs is made of heavy-cast steel (SCW480). The deck sockets are provided with a special primer. This primer ensures that the bottom plates do not rust. There is no need to remove the primer before applying the weld. However, the additional smoke formation can occur during welding. If desired, the primer can be removed locally.

Technical drawing available

The exact dimensions of the Bottom plate DF-31 can be found on the technical drawing in .pdf format. There is also a 3D drawing available as a .stp file. This allows the DF-31 to be loaded into a technical drawing package for the design of custom structures.

For questions and free advice, our team is ready to help you. Please contact us via +31 (0) 10-495 0000 or sales@navacqs.com to discuss the possibilities. You can also contact us if you are looking for a product that is not on our website.

The Deck Socket DF-31 is similar to the following articles from other manufacturers

FR-31B

Bodemplaat DF-31

The Deck Socket DF-31 bottom plate makes it possible to use the Dovetail Twistlock BF-11 and the U-Frame Lashing Eye (D-Ring) LP-91-45. The deck of a ship (or another surface) thus remains free of protruding twistlocks or lashing eyes. Thanks to the well-thought-out design and use of materials, the DF-31 bottom plates have a tested breaking strength of no less than 500 kN or 50T. The frame is made of cast steel and finished with a protective primer. The exact dimensions of the Bottom plate DF-31 can be found on the technical drawing.

Makes the BF-11 Twistlock and Lashing Eye LP-91-45 demountable

The Deck Socket DF-31 has been specially developed for use in combination with the Dovetail Twistlock BF-11. With this twistlock, a sea container can be secured on deck. The DF-31 bottom plate ensures that the twistlock can be disassembled. The deck socket is designed in such a way that the BF-11 can easily be slid into the socket. This keeps the deck of a ship (or another surface) free from protruding twistlocks or lashing eyes.

The Deck Socket DF-31 also serves as the basis for the U-Frame Lashing eye (D-Ring) LP-91-45. This 36-tonne lashing eye is used to lash cargo. This can be useful in a situation where different types of loads are being transported. For example, a container can be transported on the same deck one day and a steel structure has to be lashed the next day. The base plate DF-31 is supplied with an inner angle of 45 degrees as standard. The Deck Socket DF-31 is optionally available with an angle of 55 degrees.

Both the LP-91-45 and the BF-11 can only be slid in one direction in the bottom plate.

The plates must be welded in the opposite direction. When the Dovetail Twistlock is placed in the opposite direction in the bottom plate and the container is in place, shifting is no longer possible.

Easy to weld to ship deck or construction

The versatile base plates from Navacqs can easily be welded to a steel surface. For example on the deck of a ship or a floating pontoon with offshore equipment. In addition to applications on the water, the Deck Socket DF-31 can also be welded on trailers to anchor self-designed structures. The welding instructions can be downloaded here.

Please note: the Deck Socket DF-31 is not suitable for road transport. For this application use a suitable twist lock with security.

High breaking strength of 500 kN (T) / 420 kN (SH)

Heavy forces can stand on the Dovetail Twistlocks and U-Frame Lashing Eyes. Especially when containers or structures are subject to severe weather influences such as strong wind in combination with a. have to cope with waves. The bottom plate DF-31 is the connecting factor between the twistlock and the ground. Thanks to the well-thought-out design and use of materials, the DF-31 bottom plates have a tested breaking strength of no less than 500 kN or 50T.

Manufactured from steel with primer coating

The Base plate DF-31 from Navacqs is made of heavy-cast steel (SCW480). The deck sockets are provided with a special primer. This primer ensures that the bottom plates do not rust. There is no need to remove the primer before applying the weld. However, the additional smoke formation can occur during welding. If desired, the primer can be removed locally.

Technical drawing available

The exact dimensions of the Bottom plate DF-31 can be found on the technical drawing in .pdf format. There is also a 3D drawing available as a .stp file. This allows the DF-31 to be loaded into a technical drawing package for the design of custom structures.

For questions and free advice, our team is ready to help you. Please contact us via +31 (0) 10-495 0000 or sales@navacqs.com to discuss the possibilities. You can also contact us if you are looking for a product that is not on our website.

The Deck Socket DF-31 is similar to the following articles from other manufacturers

FR-31B

|

Product

|

Deck socket DF-31

|

|

Breaking strength

|

500 Kn (≈50 T) |

|

Material

|

Cast steel |

|

Finish

|

Blasted and treated with primer (directly weldable) |

|

Weight

|

3,7 Kg

|

|

Quality steel

|

SCW480

|

Tailor-made quotation

Do you have specific wishes regarding the Deck Socket DF-31? We are happy to advise you.